Flyber is expanding production capacity in the UK

News

Date Updated: 10.04.2023

Read time: 3 min read

“This expansion isn’t just about square footage—it’s about building the infrastructure to support the next decade of aerospace growth, right here in the UK.”

Andrea Savi, Co-founder & COO

Scaling to meet rising demand

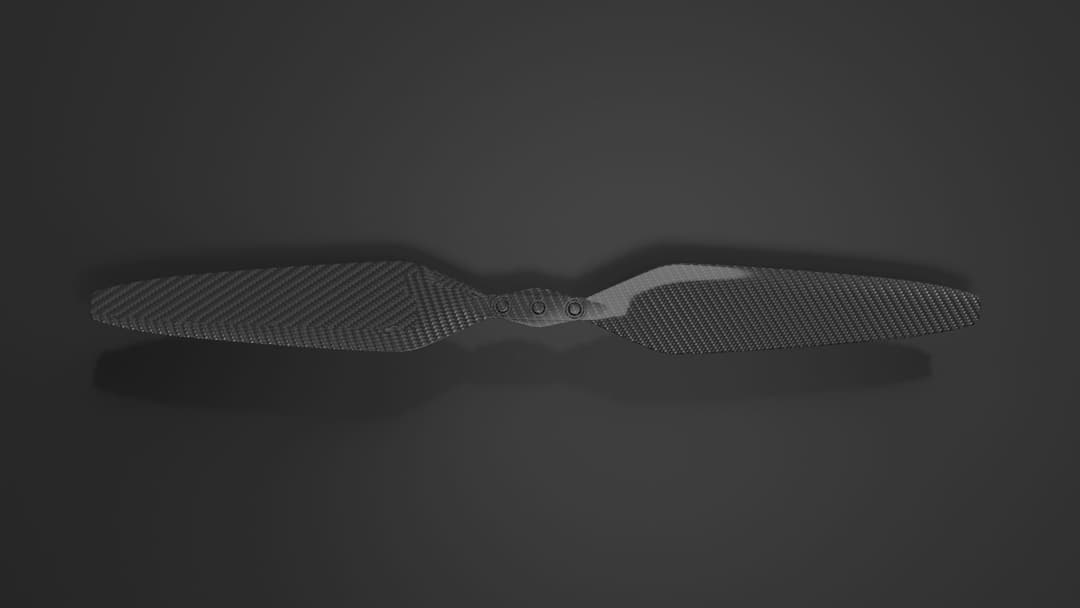

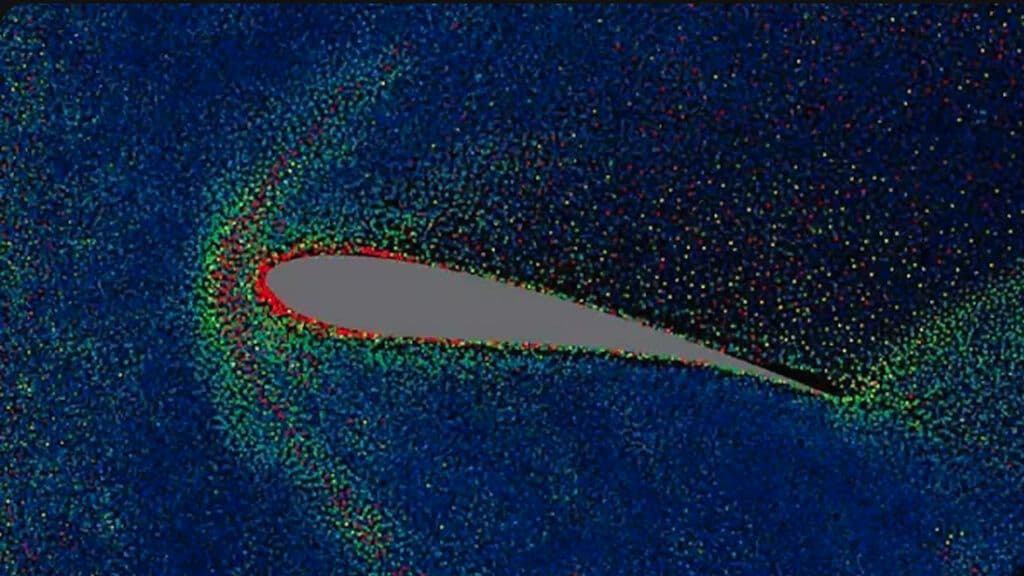

To meet growing interest across the drone and eVTOL sectors, Flyber is making significant investments in our UK production footprint. Our new manufacturing capacity in Milton Keynes will allow us to produce greater volumes of composite rotor blades—while maintaining the same level of precision and reliability we’re known for.

With demand increasing from both civil and defence markets, scale and repeatability have never been more critical. This new capacity ensures we can serve more partners—without sacrificing quality or lead times.

UK-made, globally trusted

Being based in Britain gives us a strategic edge. It means proximity to our customers, access to top engineering talent, and a resilient, transparent supply chain.

By investing in our local ecosystem, we’re also contributing to the UK’s aerospace sector as a whole—creating jobs, deepening expertise, and supporting sovereign capability in composite component production.

Technology meets throughput

Our new facilities aren’t just bigger—they’re smarter. We’re integrating robotics, real-time process monitoring, and digital quality control systems across our lines. This allows for higher throughput without adding variation.

From moulding and curing to trimming and finishing, every step is tracked, traceable, and built for consistency. This level of control is essential for aerospace-scale growth.

Built for the long haul

This expansion is a reflection of our long-term vision. Flyber isn’t chasing short-term demand spikes—we’re building a foundation for sustained leadership in advanced composite manufacturing.

As AAM and defence needs accelerate, we’re ready with the infrastructure, the team, and the technology to lead.