Why Flyber's sustainable manufacturing is reshaping aerospace

Sustainability

Date Updated: 03.04.2025

Read time: 5 min read

“We didn’t just want to make more efficient rotor blades—we wanted to rethink how aerospace components are made altogether. Sustainability isn’t a compromise. It’s a competitive advantage.”

Andrea Savi, Co-founder & COO

Redefining sustainability in aerospace manufacturing

Flyber’s commitment to sustainability is built into every stage of our process. From material selection to final assembly, we’ve engineered a production system that aligns cutting-edge aerospace standards with environmental responsibility.

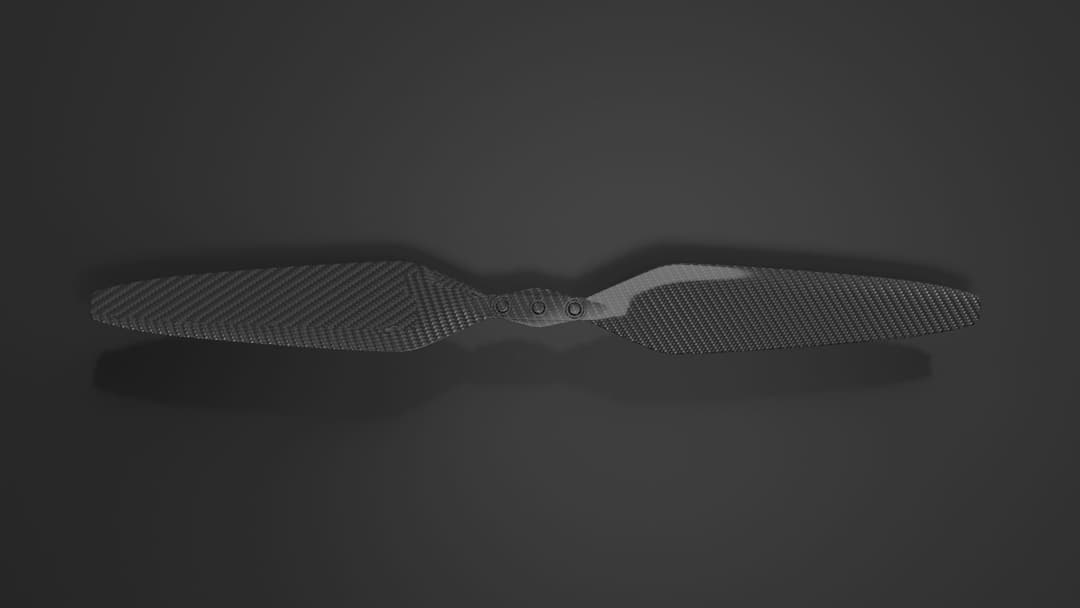

We start by sourcing advanced thermoset and thermoplastic composites that offer high strength-to-weight ratios while reducing raw material waste. These materials are not only optimised for performance in the air but also offer improved recyclability over traditional aerospace components.

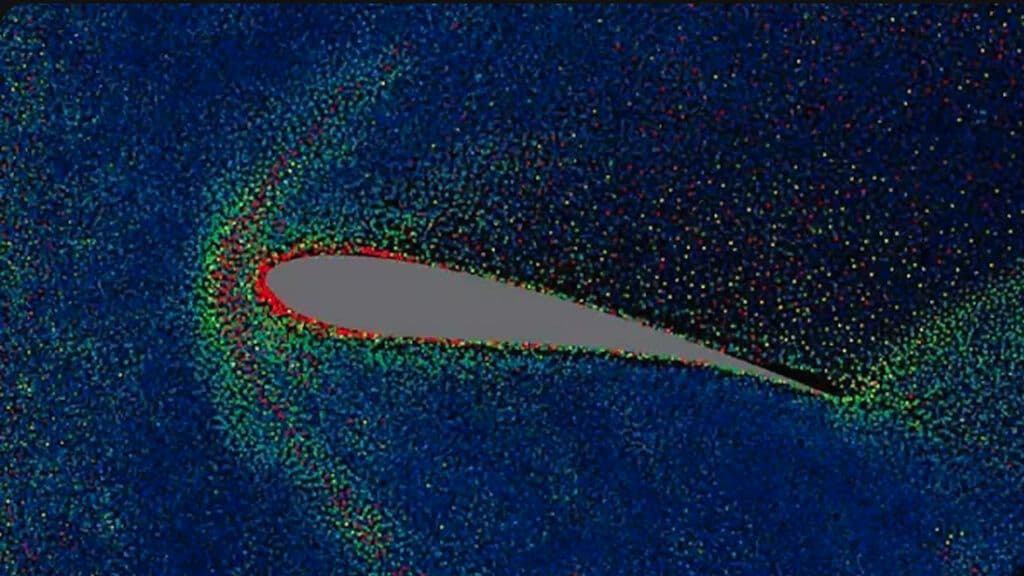

Our in-house design for manufacture (DfM) principles allow us to create rotor blades that use less material without compromising on durability or aerodynamic efficiency. Lighter blades mean better energy use in flight—directly supporting greener aviation outcomes.

Localising production for global impact

A major part of our sustainability advantage lies in our fully UK-based supply chain. By designing, testing and manufacturing entirely within Britain, we reduce emissions tied to shipping and logistics. It also allows us tighter quality control and faster iteration loops.

Our manufacturing facilities integrate waste reduction measures, including optimised nesting for composite cutting and controlled resin flow during layup. Even small efficiencies add up when scaled across production runs.

Aligning with industry needs and regulation

The aerospace sector is under mounting regulatory and market pressure to decarbonise. Governments, military buyers, and OEMs are now scrutinising not just the emissions of aircraft in the sky, but also how components are made on the ground.

Flyber’s sustainable manufacturing approach doesn’t just help clients meet their ESG targets—it helps them win bids. When sustainability, reliability and UK-based sourcing are all on the checklist, we tick every box.

Scaling production without scaling emissions

As demand for AAM and eVTOL platforms increases, the pressure is on suppliers to scale responsibly. Flyber is expanding manufacturing capacity without increasing our environmental footprint. Our composite tooling processes are designed for reuse and high repeatability, allowing us to deliver large batch orders with minimal waste.

We’re also investing in automation across key steps of our blade manufacturing—such as fibre placement and trimming—ensuring precision at scale while keeping material offcuts to an absolute minimum.

End-of-life thinking from the start

Sustainability doesn’t end when a rotor blade leaves the factory. We’re working towards circular production models, with R&D focused on reclaiming fibres from end-of-life products and reintroducing them into the manufacturing cycle.

By designing for disassembly and recyclability from the outset, we’re preparing for a future where aircraft components are not just high-performing, but regenerative.

A blueprint for future-ready aerospace

Flyber isn’t just adopting sustainable practices—we’re shaping what responsible aerospace manufacturing looks like in a world that demands cleaner, smarter technologies. Whether it’s supplying UAV developers or collaborating on defence-grade projects, our approach ensures performance never comes at the planet’s expense.

This isn’t about compromise. It’s about creating components that lift more than aircraft—they lift the standard for the entire industry.