Flyber delivers its first prototype rotor blades for UAVs

News

Date Updated: 15.09.2023

Read time: 4 min read

“This wasn’t just a delivery milestone—it was proof that our composite expertise can move from concept to real-world application fast. We’re shaping what next-gen flight will feel like.”

Rowan Carstensen, Co-founder & CEO

A major step forward in UAV performance

Our successful delivery of Flyber’s first optimised composite rotor blade prototype marks a key point in our growth—and in the evolution of UAV performance standards.

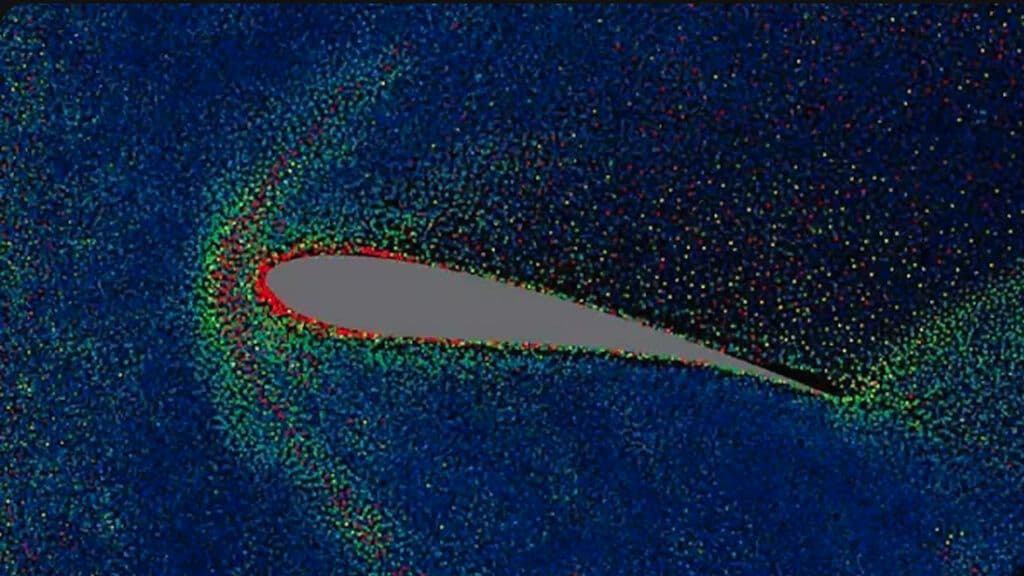

Designed for electric and hybrid UAV platforms, this prototype integrates structural efficiency, weight savings, and improved aerodynamics. It’s not just lighter—it’s tuned to generate more lift per watt of power input, translating directly into longer flight times and quieter operation in the field.

We developed the blades using high-pressure resin transfer moulding and precise fibre alignment techniques, achieving a uniform structure that outperforms traditional layups.

Fast iteration, full control

One of our core capabilities is speed—with precision. Because Flyber operates a vertically integrated model, we’re able to move from concept and CAD to physical blades in weeks, not months. That’s invaluable to aerospace partners needing to iterate fast and validate quickly.

Our Milton Keynes facility handled every stage of the prototype build in-house. That includes tooling, moulding, quality control, and performance validation—all under one roof, in the UK.

Real-world testing and insights

We’ve collaborated closely with industry partners during the prototyping phase, integrating their real-world UAV operating requirements into our design parameters. Feedback loops are tight, and we’ve used them to tune the blade’s twist profile, edge geometry and core materials for optimal real-world results.

The prototype’s successful delivery was paired with internal vibration and fatigue testing, simulating flight cycles in demanding conditions. The early data is promising: improved acoustic performance and a measurable uplift in efficiency across standard mission profiles.

Ready for what’s next

Prototype delivery isn’t the finish line - it’s the foundation. With these first units in the air, we’re now scaling up for low-rate production while continuing to validate under various flight regimes and load profiles.

The goal is simple - blades that don’t just look good on paper, but deliver performance in the sky, reliably and repeatedly.