The future of UAV propellers: What sets Flyber apart

News

Date Updated: 20.08.2023

Read time: 6 min read

“We’re not just selling propellers—we’re helping UAV developers push the boundaries of what’s possible. Every innovation we make is about giving our partners an edge.”

Andrea Savi, Co-founder & COO

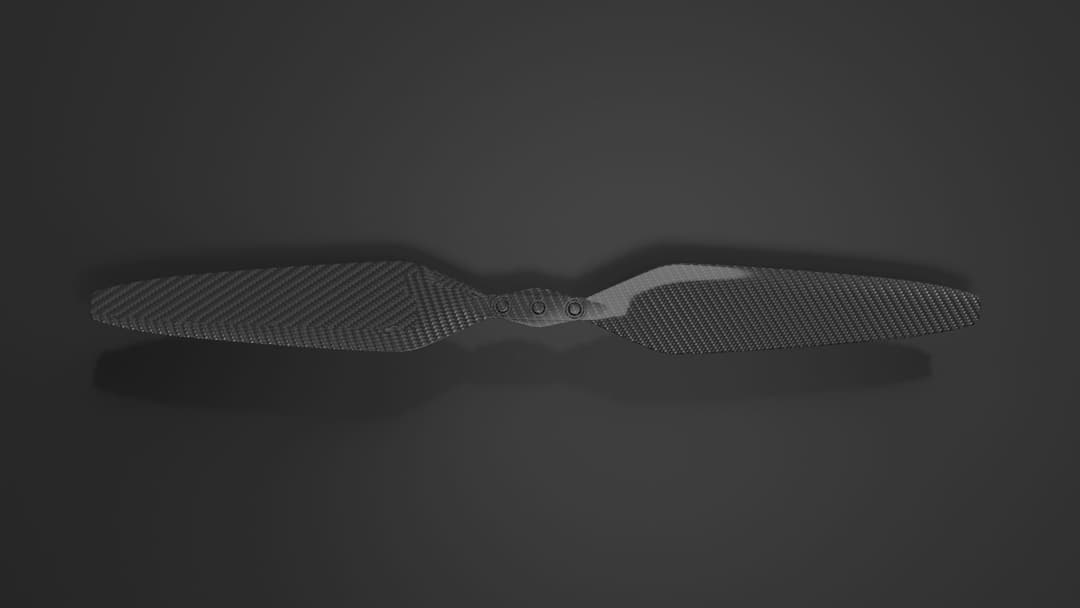

Designed for what’s next in UAVs

The UAV market is moving fast. Applications are getting more complex, payloads heavier, and endurance expectations higher. At Flyber, we’ve engineered our propeller designs to meet—and exceed—these shifting demands.

Our blades offer industry-leading design flexibility, allowing us to tailor pitch, chord, and blade count to exact customer profiles. Whether you’re flying VTOL drones for delivery or surveillance-class UAVs, we optimise around what really matters: lift, noise, power draw, and longevity.

Why flexibility matters

No two UAVs are the same—and neither should their blades be. We’ve built parametric design systems that adapt to evolving airframe geometries and mission specs. Need higher static thrust? We tune the root shape. Chasing acoustic reduction? We design for tip geometries that manage vortex shedding.

It’s this attention to detail that’s helped Flyber gain traction as the go-to choice for forward-looking UAV manufacturers.

Built to scale, built in Britain

Performance is one thing. Deliverability is another. Our manufacturing capabilities are built for both. With a production line capable of high volumes and low tolerances, we produce thousands of blades per month—all from our UK facility.

That means no overseas lead times, no unpredictable customs delays, and full transparency throughout the process.

Quality, that’s measurable

Every Flyber blade is subject to rigorous testing—from digital simulation to destructive lab tests. We validate every rotor’s structural performance, dimensional accuracy, and fatigue tolerance. Our composites meet or exceed aerospace-grade specs.

And because we’re vertically integrated, when our partners need to tweak a design, it’s a quick call—not a full restart.

This is what sets Flyber apart: real performance, real results, ready to scale.